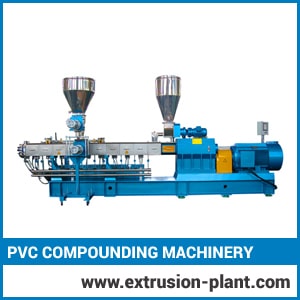

Having rich fabrication experience for the production of big plants and machinery, we offer an exclusive range of compounding plants with rigid construction. It contains excellent mixing characteristics.

Automated, PVC Compounding Plant at Best Price

It contains great flexibility and the best compression quality. Our Compounding Plant, PVC compounding plant automation, is available with excellent adaptability for varied kinds of mixing the batch of different sizes.

Key Functions of a Compounding Plant

- Polymer Base Handling

- Handling of raw polymers such as PVC, PE, PP, EVA, ABS, etc.

- Automated feeding and transfer systems for bulk material movement.

- Ingredient Blending

- Accurate dosing and weighing of additives such as:

- Stabilizers

- Plasticizers

- Fillers

- Flame retardants

- Color masterbatches

- Antioxidants and UV stabilizers

- Accurate dosing and weighing of additives such as:

- High-Shear Mixing & Extrusion

- Intensive blending through twin-screw or single-screw extruders

- Melt compounding to ensure homogeneity

- Cooling & Pelletizing

- Cooling conveyor, air or water bath cooling

- Strand or die-face pelletizing to form final pelletized compound

- Quality Control & Testing

- In-house lab testing for density, melt flow index (MFI), color, tensile strength, etc.

- Ensures consistent product quality