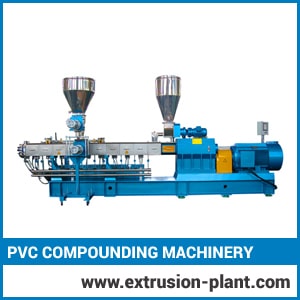

PVC compounding machinery is available with different production capacity and container capacity. It is available with different charge batch capacity from kg to 1000 kg. It is available with PLC/SCADA based control system that facilitates with the system to access the record of the production and material used. It is also used better to make batch records and records of printing.

PVC Compounding Machinery

Unique designs of mixing bowl are provided with large bottom radius and fluidizing blades. It offers the shortest possible time for each cycle. Best grade material ensures good performance with lower power consumption.

It offers minimum wear and tear. Enhanced service life is offered with the precisely constructed unit, Pipe extrusion machinery. It also offers the best performance with negligible maintenance.

| Feature | Description |

| PLC/SCADA Automation | Ensures consistent processing and real-time control |

| High Mixing Efficiency | Uniform dispersion of additives |

| Energy Efficiency | Optimized power consumption during heating/mixing |

| Modular Design | Flexible integration with different lines |

| Corrosion-resistant Build | Stainless steel contact parts for hygiene & durability |

| Safety Interlocks | Overload, temperature & pressure protections |